주)페트로산업 메인 네비게이션

페트로산업 sub navigation

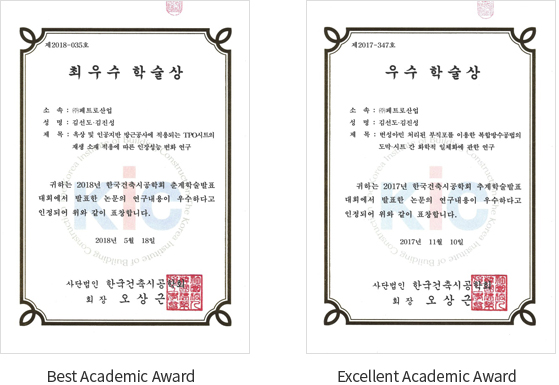

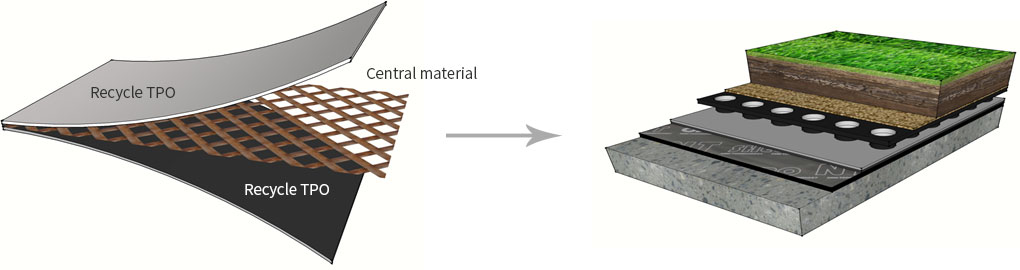

NT Root Barrier Method (NT GREEN SYSTEM)

NT Root Barrier Method applied regenerative TPO for the purpose of ensuring eco - friendly by utilizing cyclical resources. It was manufactured by polymerization reaction using metallocene catalyst, not by simple mixing, and applied a regenerated Reactor TPO for excellent materiality. It also maintains most of its original performance after regeneration, and applied a physical performance.

|

Characteristic

Scope of application

Packaging Unit

|

|

Quality Standard

- KSF 4911(2017) : Synthetic Polymer Waterproof Sheet

| Item | Type | ||||

|---|---|---|---|---|---|

| Reinforced Composite Type | |||||

| Tensile Performance | Tensile Strength (N/㎜) | Above 24 | |||

| Coefficient of Expansion (%) | Above 15 | ||||

| Tearing Performance | Tensile Strength (N) | Above 50 | |||

| Temperature dependence | -20℃ | Coefficient of Expansion (%) | Above 7.5 | ||

| 60℃ | Tensile Strength (N/㎜) | Above 10 | |||

| Heat Flexibility | Flexibility (㎜) | Tension | Below 2.0 | ||

| Shrink | Below 4.0 | ||||

| After Heat Treatment Tensile Performance | Tensile Strength (%) |

Heat Treatment | Above 80 | ||

| Promotional Processing | Above 80 | ||||

| Alkali Treatment | Above 80 | ||||

| Coefficient of Expansion (%) | Heat Treatment | Above 70 | |||

| Promotional Processing | Above 80 | ||||

| Alkali Treatment | |||||

| Above 80 | |||||

| Heat Properties during tension | Heat Treatment | No cracks in any test specimen during heat treatment | |||

| Promotional Processing | |||||

| Ozone Treatment | |||||

| Tensile Performance | Tensile Strength (N/㎜) |

Untreated | Above 24 | ||

| Heat Treatment | Above 19 | ||||

| Alkali Treatment | Above 19 | ||||

Transportation and Storage

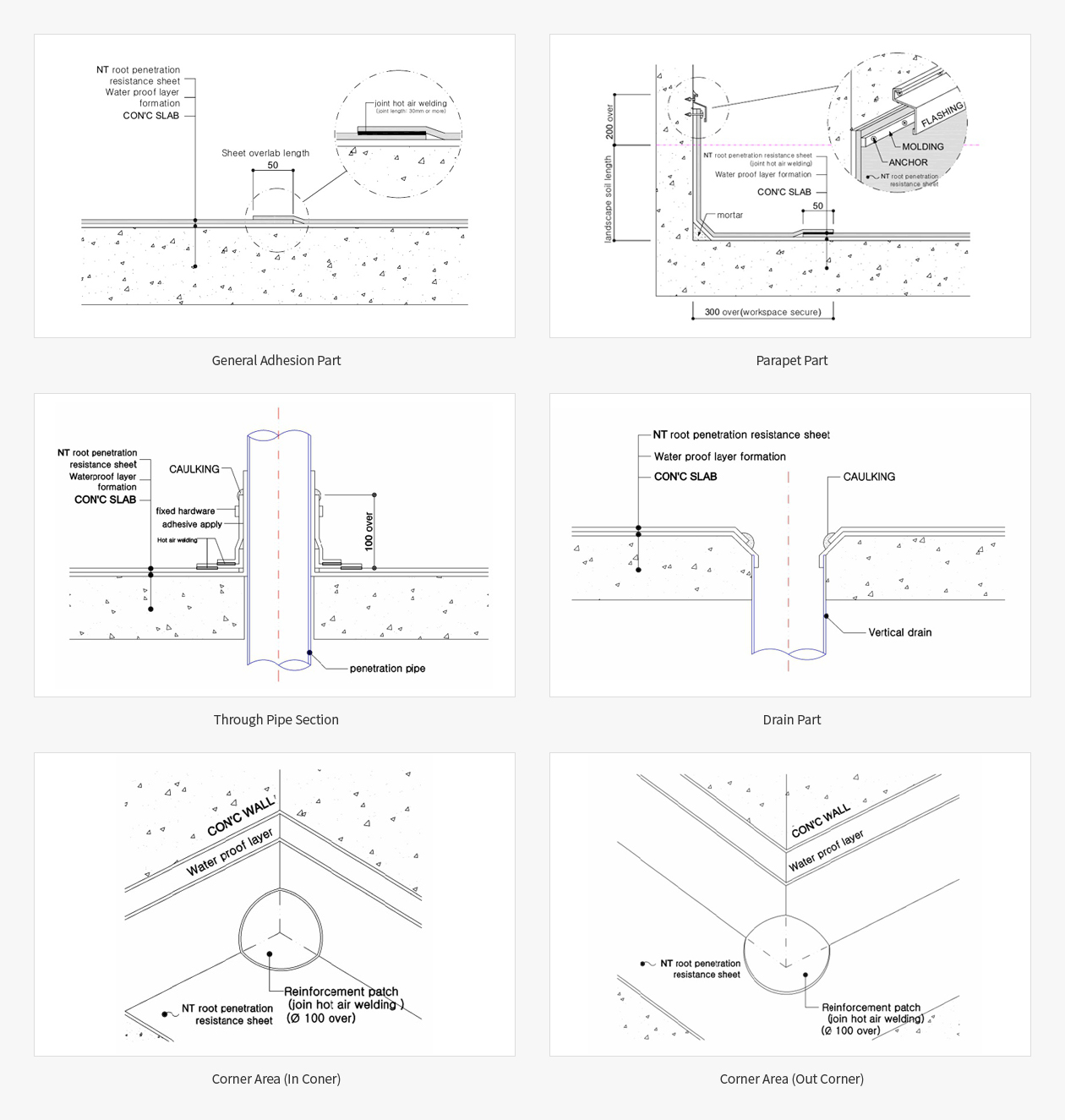

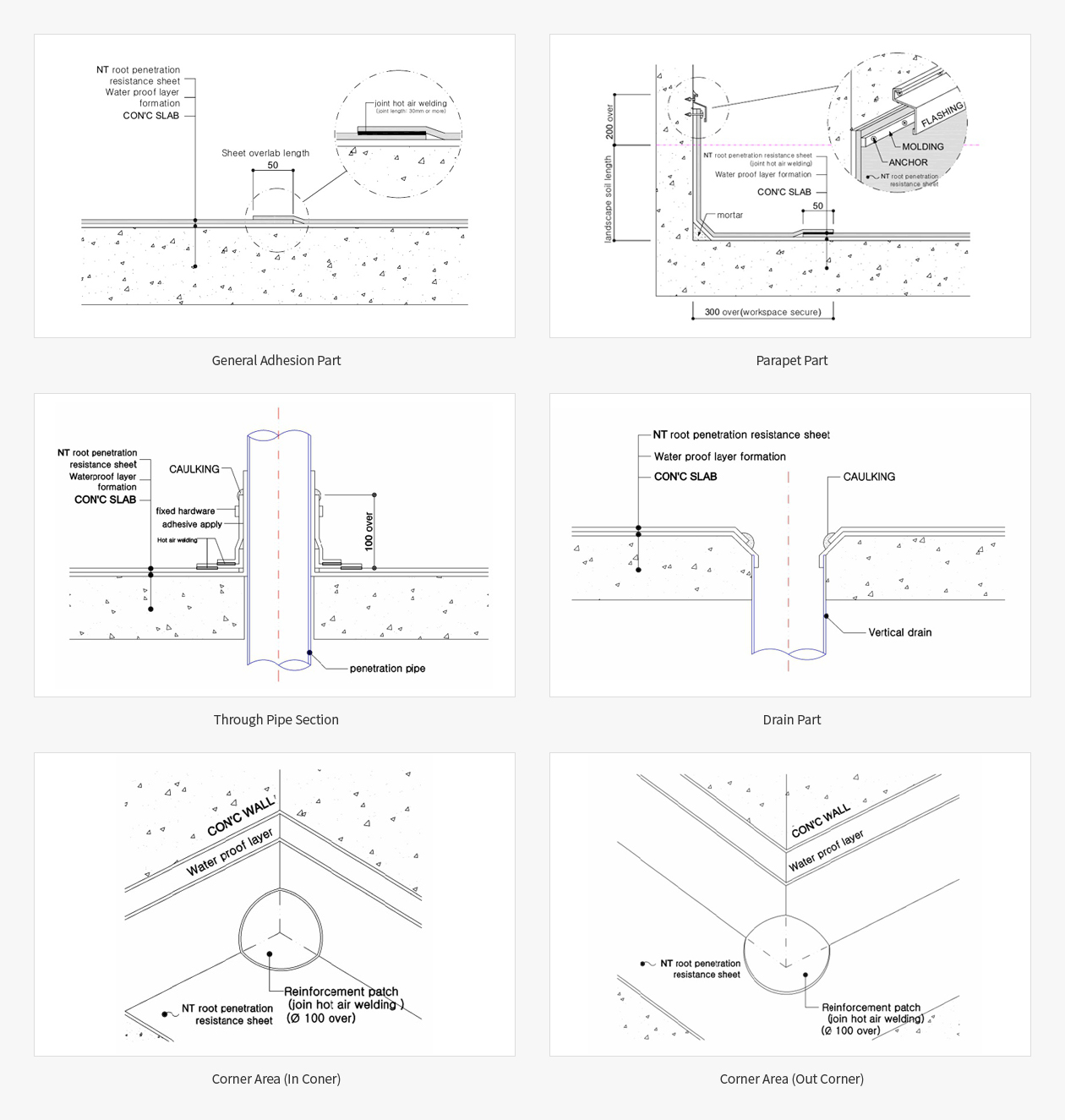

Construction Details

Awards