주)페트로산업 메인 네비게이션

페트로산업 sub navigation

Petro Sheet

Petro Sheet is a waterproof sheet made by cooling and forming at room temperature by adjusting thickness and length according to specifications after sufficiently penetrating specially pressed central gas into a highly concentrated and improved asphalt compound.

The Petro Sheet is formed with multi-layer waterproof structure and is developed considering work stability, construction feasibility, economy, durability, and deformability according to structure change, so it is a good waterproof sheet with very wide scope.

Petro Sheet has made inroads into the global waterproof material market under its own brand, and is a high-end waterproof sheet currently exported to countries around the world.

- Through a thorough experiment, the company produces the best improved asphalt compound that governs the materiality of the waterproof sheet by selecting the appropriate mixing cost Mix Proportions, the use of good raw materials, and the selection of special mixing facilities and mixing conditions.

1. Excellent Improved asphalt compound

- With the most basic materials to have as a waterproof material, flexibility and elasticity are maintained as much as possible after a long period of time, so they can actively adapt to the changes around the universal structure, such as cracks, vibrations, shrinkage and expansion.

2. Excellent durability

- It is most suitable for domestic climate conditions, where temperature changes are great because it is not broken at low temperatures or flowing at high temperatures.

3. Wide Thermo-sensitivity

- As with ordinary vulcanized rubber, the restoration of external physical penetration is rapid and the change of structure with excellent extension force is highly adaptable to the change of structure, thus complementing the durability of waterproofing material according to seasonal changes.

4. Excellent elasticity and elongation

- Because construction is easy by manufacturing to a certain standard, it can produce waterproof effects with the lowest construction cost by minimizing the construction period and the number of people.

5. Affordable constructivity

- KS F 4917 (2016) : Improved asphalt waterproof sheet

| Classification according to use | Exposure Layer Waterproof and Non-exposure layer waterproof | Exposure multiple layer waterproof and non-exposure multiple layer waterproof | Test Items | |||||

|---|---|---|---|---|---|---|---|---|

| Classification according to material composition | TYPE A | TYPE B | TYPE A | TYPE B | 5.5 |

|||

| Tensile Strength | 인장강도 N/㎜ |

Untreated | Above 8.0 | Above 2.0 | Above 5.0 | Above 2.0 | ||

| After heating | Above 80% of untreated test value | |||||||

| After soaking alkali | ||||||||

| Coefficient of Expansion % | Untreated | Above 15 | Above 400 | Above 15 | Above 400 | |||

| After heating | Above 80% of untreated test value | |||||||

| After soaking alkali | ||||||||

| Tensile Product N·%/㎜ | Untreated | Above 250 | Above 1,200 | Above 200 | Above 1,200 | |||

| Tearing Performance N | Above 20 | 5.6 |

||||||

| Heat-Resistance Performance | Roll Down Length ㎜ | Below 5 | 5.7 |

|||||

| Appearance | Will not spill or shoot out | |||||||

| Fatigue Resistance | No cracks, no tear, no fracture | 5.8 |

||||||

| Dimensional stability | Dimensional Change Rate % | 0.0 ± 1.0 |

5.9 |

|||||

| Appearance | No creases, bending, or detachment between layers | |||||||

| Joint Performance N/㎟ | Above 5.0 or above 70% of untreated tensile strength | 5.10 |

||||||

| Pitting Performance | No hole | 5.11 |

||||||

| Type | Composition | Standard (Thickness ㎜×Width m×Length m) |

Use | Chracteristic |

|---|---|---|---|---|

PS-T |

|

2.0×1.0×10~4.0×1.0×10 (Changing sheet specifications) |

Roof and Underground water Subway Structure Underground roadway, communal district parking lot Telecommunications, power outlets, |

excellent tensile strength, Flexible sheet Suitable for high structures Powerful adhesion, perfect for the structure. Adhesive to form a permanent waterproof layer |

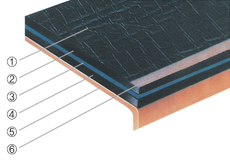

| 1. Polyethylene film 2. Improved Asphaltic Compound 3. Central reinforcement (P.P. Fabric) 4. Improved Asphaltic Compound 5. Releasing Film 6. Overlap Releasing Film |

||||

PS-TP |

|

2.0×1.0×10~4.0×1.0×10 (Change sheet specifications) |

Important Structure Waterproof Roof and Underground Waterproofing Subway structure. Underground roadway, communal district Parking Lot Cable Tunnel, Power | Excellent for fatigue resistance and index stability for repetitive construction of structures Asphalt-friendly by central reinforcement materials preventing separation of the middle |

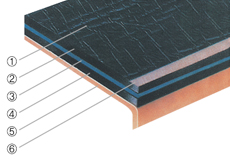

| 1. Polyethylene film 2. Improved Asphaltic Compound 3. Central reinforcement (Polyester Fabric) 4. Improved Asphaltic Compound 5. Releasing Film 6. Overlap Releasing Film |

||||

PS-S |

|

2.0×1.0×10~4.0×1.0×10 (Change sheet specification) |

Underground parking lot slabs Waterproof of the large part Waterproof of roof and underground of general buildings Waterproof for all structures | Form waterproof layer that is independent from the structurewhile constructed as floating method of construction Excellent heat-resistance, Excellent workability |

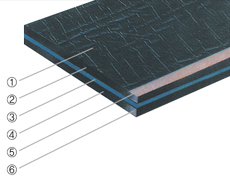

| 1. Polyethylene film 2. Improved Asphaltic Combs 3. Central reinforcement 4. Improved Asphaltic Compound 5. Releasing Film 6. Overlap Releasing Film |

||||

PS-B |

|

1.6×1.0×10~2.0×1.0×10 (Change sheet specifications) |

Roof waterproof construction | It is easy to construct on slopes or narrow spaces and can be cut and used. |

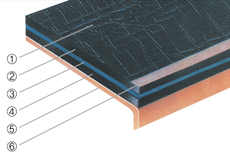

| 1. P-P Fabric 2. Improved Asphaltic Compound 3. Central reinforcement (P.P. Fabric) 4. Improved Asphaltic Compound 5. Releasing Film 6. Overlap Releasing Film |

- The base shall be completely dry and free from bumps.

- The base must be flat and the water gradient should be at least above 1/100.

- The corner, and the connection shall make an R base.

- After V-CUT, fill the cracks with the mortar.

- Do not expose the wires or nails. Clean up any foreign substances on the ground.

1. Cleaning up the base

- Use a brush or roller to evenly apply the Petro Primer.

- The applied Petro Primer shall not be smeared in the hands.

- If it rains after applying primer, or left for a long period of time, the primer shall be applied again.

2. Apply Petro Primer

- Areas such as corners, drain parts, and Exp-Joints should be sufficiently reinforced before the sheet operation.

- After verifying that the reinforcement sheet is perfect, perform the sheet work.

3. Reinforcement attachment

- The construction temperature of the sheet shall not be more than 0°C.

- Before construction, dry the sheet by identifying the area of the pasting and the area of the construction site.

- Clip the sheet from a low place to a high place, depending on the flow direction.

- Extend the sheet, position it, and heat it up to 30cm with a torch, then peel off the sheet.

- Make sure that the overlapping area of the sheet is not less than 10cm, then peel off the side overlap and use a torch to fully bond.

- Use a torch to reattach by lifting the sheet with trowel on the parts that are not completely connected.

- The area where the horizontal floor meets the vertical wall shall be attached at least 10cm above the vertical wall, and the vertical-downward seat shall be lowered by more than 10cm horizontally.

- The vertical wall area shall be sealed after the sheet has been inserted into the groove of the vertical wall to prevent the sheet from flowing down or separating from the wall.

- Be careful not to damage the sheet by excessive heat during thermal fusion, and it is ideal if asphalt melts within 2 to 3mm of the end of the overlap after bonding.

- When the sheet construction is finished, the construction conditions must be re-checked before the protective molding construction.

4. Construction of Petro Sheet

- When the sheet construction is complete, the horizontal floor shall be protected by at least 30 mm, and the vertical wall side shall be used to prevent damage to the sheet by stacking 0.5B bricks.

- The slope of the surface shall be more than 1/100 so that the flow of water is smooth.